Design, make and document a press-fit construction kit.

Click here to download Wheel of Knowledge - 3mm ply

Click here to download Glasses Rack - 4mm ply

1. Hand sketch & Dimesion

2.

CAD.

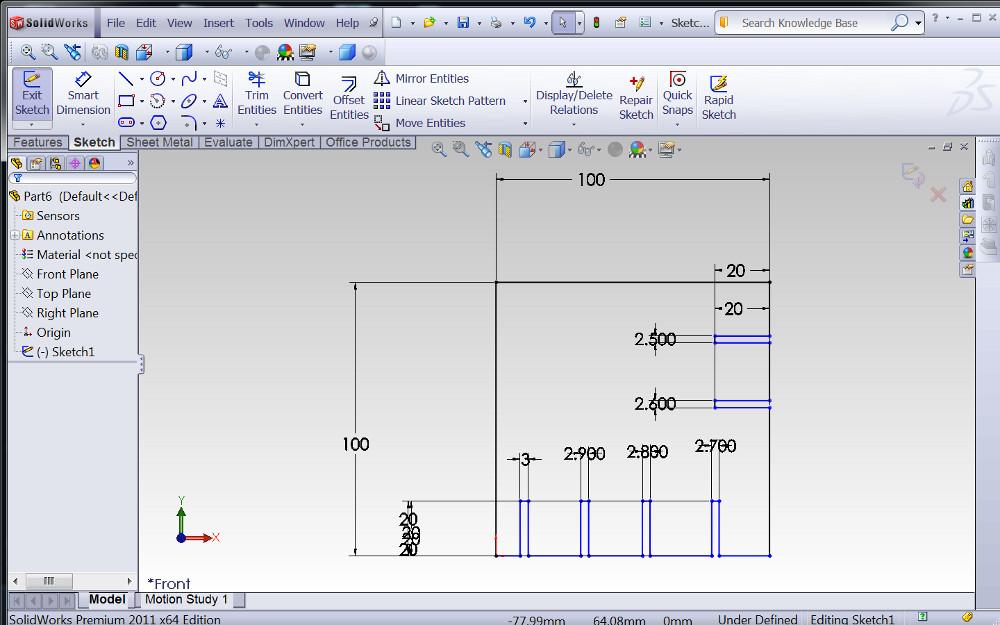

In order for the press fit to have an interference fit (i.e. friction to keep the parts together) A variety of notch sizes must be tried until the optimum friction/inteference is found. To do this, two trial pieces were cut with notch sizes ranging from 2.5-3.0mm in 1mm incriments, for a workpiece of 3mm thickness. 2.7mm provided the best fit.

Each of the design elements were then sketched in separate pages.

The elements were then combined in a new sketch with the "copy all" and "paste" commands. Here some nesting was also done to minimise material wastage.

"Save as" .dxf.

3. Cut

Send to lazer cutter - depending on the set-up you may require additional processing of the files for layers and or arrangement of the components on the sheet. Here not covered.

Run file

4. Assemble

4mm ply - 3.7mm notches - attachment to substatre needs refinement